Project Log: Saturday,

October 17, 2009

Home Page >

The Project >

Project Logs > 10/17/09 |

It was exciting to actually start

work on the boat. I'd looked forward to it all week.

I spent the first part of the day collecting various tools

and gear I thought I'd need for the interior removal:

angle grinder with cutoff wheels; reciprocating saws and

blades; impact driver and various hand tools; safety

equipment; prybars and hammers. Earlier in the week,

I'd set up some cords and work lights inside; the

"beginning" had been 5 years in the making, so I guess I was

ready.

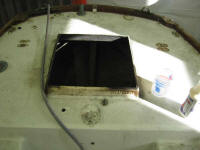

I was already sick of the fiberglass forward

hatch and lazarette hatch, so the first thing I did was

remove these; this was easy, as the hinges were secured to

the deck with only self-tapping screws. Then, I

removed the companionway slide and the copper or bronze

tubes on which it slid, and set these three hatches aside.

I didn't anticipate reusing any of them, but for the moment

they went to what was to become a startlingly small "save"

pile. |

|

Onwards. The next thing I did was to remove

the remaining countertop inside the companionway, the one

containing the galley sink, and the old companionway ladder.

This structure was so weak that I didn't want to even have

the opportunity to step on it and kill myself on the way in

or out of the boat, which I'd been gingerly doing over the

years when I'd come into the boat for one reason or another.

Out it went with virtually zero effort; for the moment, I

installed a 6' stepladder in its stead, though soon I'd

build a construction ladder to use for the duration of the

project. |

|

The badly-burned overhead liner was bugging me, as

every time I walked through the interior the spidery,

dangling threads of fiberglass mat would brush my head in an

irritating manner. So I decided that at least the aft

section of the overhead liner had to be the next thing to go

before I continued removing the other interior components.

I used an angle grinder equipped with a metal cutoff wheel

to quickly cut the liner into manageable pieces, and pulled

it down. It came away easily, revealing a

soot-blackened mess of ugly liner adhesive, melted wiring,

and the expected raw glasswork. In four sections, I

removed the entire liner as far forward as the doghouse

bump, taking care of the nastiest portion. The "snow"

in the air in these photos is airborne dust reflected by the

camera flash. |

|

After opening the large shop door to evacuate dust

from the liner cutting, and to dispose of the pieces and

parts I'd removed so far, I continued work on the galley,

and removed the countertop and cabinetry on the port side,

along with some of the wooden trim on the pilot berths and

settees. This all came easily. In the midst of

this, my friend John arrived to help with the demo--he'd

been as or more excited about this process than I during the

past several hears, and had enthusiastically volunteered to

help out. |

|

I moved on to continue removing the settees and

pilot berths while John cleaned up more of the debris on

deck and unfastened the remaining ceiling slats along the

hull in the main cabin. To continue the settee

removal, I had to buzz some more tabbing where the plywood

was secured to the hull, after which the assemblies came

apart with relative ease. I completed first the

starboard, then the port sides; water had accumulated in the

space beneath the settees, and ran out once I released the

tabbing from the hull with a chisel; the secondary polyester

resin bonds securing the tabbing and interior components

were as tenuous as one would expect, and once a section was

started, it was typically possible to rip the remainder away

by hand, or with minimal chisel intervention. |

|

With the settees and pilot berths out of the way, I

cut the tabbing on the port galley bulkhead and removed it.

The bulkhead was 1" fir plywood in very good condition--as

were all the remaining bulkheads. One simply cannot

find fir plywood of this quality today. If I'd wanted

to keep the original layout of the interior, there would

have been no need to remove these bulkheads. But I

planned on a clean slate for the project, so out they came. |

|

Then, I moved on to one of the more humorous parts

of the day: removing the icebox. It was funny to

start to pry the plywood away from the molded tub unit only

to have large volumes of popcorn-sized bits of styrofoam

pour out in steady streams, burying the cabin sole in a foot

of the material. The entire molded fiberglass liner

tub was surrounded by this loose stuff, which showed no

signs of ever having been a homogenous mass. I

imagined that one probably could have literally watched a

block of ice melt before one's very eyes with the poor

quality of the insulation. |

|

I removed the front (inboard) panel and tried prying

the liner tub loose, but the bottom supporting panel was

rotted and all I did was break that when I used a prybar.

Clearly, I had to remove the starboard galley

bulkhead--which formed the forward end of the icebox

unit--in order to remove the tub. So I cut the tabbing

on the forward side, after which it was quite easy to rip

the bulkhead free, releasing an avalanche of loose foam. |

|

With the bulkhead gone, it was easy to rock and rip

free the huge icebox tub, which turned out to be secured to

the rotted platform beneath with two massive blobs of resin

mixed with what looked like a week's worth of shop floor

sweepings or something. These were amusing, and I felt

I needed to save them for my personal museum of amusing boat

construction parts. |

|

I was surprised and pleased to find that the molded

tub could pass through the companionway in one piece; I was

concerned I'd have to saw it in two, but it just fit.

With this huge assembly out of the way, I filled three

full-size trash cans with the styrofoam bits, though a lot

of them found their way into the bilge.

Continuing

forward, John worked up in the v-berth removing ceiling

strips and other small pieces while I attacked the little

drawer unit and hanging locker on the starboard side

opposite the head. I found as the demolition went on

that there was a strange inverse relationship between the

structural importance of a certain piece and how securely it

was attached to the hull and adjacent interior structures:

the less important the structure was to the strength of the

boat or rig, the more securely fastened it seemed to be.

I worked harder to remove foolish shelves and non-structural

panels than I did to pry away structural bulkheads. |

|

I was bemused to note the lackadaisical structures

to which the mainmast chainplates were secured: the

aft lowers on each side were secured through a thick teak

spacer block to the bulkheads on each side, which blocks

were deteriorated from moisture--yes, even though they were

teak. The stainless steel bolts were sound enough, but

the overall installation was certainly not

confidence-inspiring.

Similarly, the main support

knees for the cap shrouds--that is, the main support for the

rig--were an abomination of cringeworthy craftsmanship and

reflected a minimalist attitude towards strength.

Replete with ragged and sharp overhanging edges of

dashed-together woven roving tabbing, these knees were

hideous, though I suppose they certainly worked well enough

for 45 years. But apparently pride in workmanship was

not a salient quality for an Allied fiberglass installer

back in the day. |

|

Next, it was time to attack the head. John was

very anxious to see this area cleared out; by now it was

about 1700, and I was growing weary from the day's efforts,

but John was an enthusiastic motivating force that could not

be denied, so I ripped the old toilet out, releasing a small

amount of questionable material into the bilge. |

|

Then, I squeezed myself into the ridiculous space

(people actually used this space?) and, with effort, tore

out the various cabinets, which in keeping with the Allied

Inverse Structure Theory were extremely well tabbed to every

available adjacent component and fought every attempt at

removal and proper access thereunto. Eventually, I

managed to remove enough clutter so that I could get in with

my angle grinder and cut at least most of the tabbing

securing the huge main bulkhead to the hull; we couldn't

tell how the bulkhead was secured to the underside of the

deck.

After cutting the tabbing on the head side, I

moved out into the saloon and repeated the process on that

side of the bulkhead, and also used a reciprocating saw to

cut through areas where I couldn't get the grinder.

Meanwhile, John unfastened a piece of aluminum angle that

was helping to secure the corner of the transverse bulkhead

to the longitudinal bulkhead that formed the inner wall of

the head, as well as the main support for the mast step

above. |

|

We soon discovered a need to cut the bulkhead just

below deck level, since it was still secured there, so I

used the saw to make that cut, after which we were able to

pry the bulkhead free by making one vertical cut to saw it

into two pieces. Triumph! John was very excited

and proud of the success at this bulkhead's removal. |

|

The next obstacle to a clear, empty boat was the

massive, 2" thick plywood longitudinal bulkhead beneath the

mast step. The tabbing was for the moment effectively

inaccessible in the depths of the bilge, so instead we just

cut the plywood at door sill height, and at the top of the

doorway. |

|

Next: the final bulkheads, at the end of the

V-berth, and the berth structure itself. With John's

continuing enthusiasm for an empty boat as a motivating

force, I passed the Sawz-All torch to him and let him make

the saw cuts required to remove these pieces, which he did

with alacrity, and before long the boat was empty (for all

intents and purposes). We found two cast iron trimming

weights, each about 50 pounds, loosely stowed in the lockers

beneath the V-berth, one of which had been poised for who

knows how long periously close to (and uphill from) the

intake seacock for the head, one good wave away from

potential disaster; the shadow of the port weight's location

is visible on the hull. We also found a bronze pipe

with bronze cap protruding from the boat's centerline

somewhere beneath the old V-berth, of unknown origin and

unknown use. |

|

The small, separate piece of overhead liner that had

been in the head was becoming annoying quickly. All

that was still securing it was the through-bolts from the

handrail on deck, so while John was sawing out V-berth bits,

I went on deck and sawed through the fasteners securing the

handrail, after previously determining that they spun from

beneath when attempting to remove the nuts. I didn't

plan on reusing the old handrails anyway.

With the

bolts cut, I could remove them--and the piece of liner.

There was a huge space between the liner and the actual

cabin trunk--about 2" worth, which space had been bridged

with more blobs of resin and floor sweeping. One of

these blobs seemed to have ended up right beneath the

opening for the molded Dorade box above, causing me to

wonder how well that vent had worked over the years. |

|

After a brief cleanup to collect the worst of the

demolition debris, it was time to sit back and marvel at the

cavernous, volumetric space. The boat looked better

already; ahead I saw challenge and limitless opportunity

(relatively speaking, of course). I'd finish up the

overhead liner removal and other bits and pieces in the near

future. |

|

Hundreds of hours of installation labor at the

factory was reduced to a couple large debris piles outside

in a fun, satisfying day's work. |

|

Total Time Today: 15 man-hours (9 hours Tim; 8

hours John) |

Previous |

Next |

|

|